Ultimaker S5

Powerful, reliable, versatile 3D printing

Discover the easy-to-use desktop 3D printer with a large build volume that delivers accurate, industrial-grade parts, time and again. With simple setup, high uptime, and reliable dual extrusion, Ultimaker S5 is the complete professional 3D printing solution.

Reconditioned 3D Printers

All our reconditioned 3D printers come with lifetime support via phone/email - the same as all of our other machines. Reconditioned 3D Printers are ex-loan/demo machines, they may have slight cosmetic imperfections but are fully working and tested in 3DGBIRE HQ repair centre. Every reconditioned 3D Printer is refurbished to the manufacturer's high standards and tested by the certified trained technical experts at 3DGBIRE. All of the reconditioned printers come with a six-month warranty.

In-house production made easy

Features summary

The Ultimaker S5 is built to run continuously and maximize uptime. Its best-in-class technical specifications deliver performance you can rely on. Designed for your success, the Ultimaker S5 is part of the complete Ultimaker 3D printing solution – one trusted by hundreds of thousands of professionals worldwide.

- Large build volume: 330 x 240 x 300 mm (13 x 9.4 x 11.8 inches)

- Compatible with high-strength glass and carbon fiber filament

- Down to 20 micron (0.001 inch) layer resolution

- Open filament system – print with any 2.85 mm material

- 4.7-inch touchscreen interface – Winner of iF Design Award 2019

Enhanced reliability

Trust the Ultimaker S5 to do its job while you do yours. Its advanced active bed leveling ensures a perfect first layer, glass doors control the airflow, and dual filament flow sensors will pause your print and notify you if you run out of material.

Composite-ready

Thanks to our pioneering alliance with global materials companies, Ultimaker S5 offers an easy way to print with the world’s most advanced filaments – including glass and carbon fiber composites.

For non-abrasive filaments, switch between build and support material in seconds, choosing from 0.8, 0.4, or 0.25 mm print cores for fast or detailed prints. To unlock more high-end applications with abrasive materials, select print core CC Red 0.6 (sold separately).

Award-winning touchscreen interface

Winner of a 2019 iF Design Award, the touchscreen interface simplifies every action with the Ultimaker S5. Step-by-step setup, navigation, and maintenance remove the need for training and deliver a hassle-free, intuitive 3D printing experience.

Unending access to Ultimaker Essentials

Ultimaker Essentials gives you the tools you need to start 3D printing at work, while meeting IT requirements. With features including remote printer management, firmware firewalls, verified plugins, and direct software support.

Start 3D printing in your business with access to all the tools you need. Increased security, workflow management, and knowledge – Ultimaker Essentials brings it to your door, with features including a limited Digital Library for easy storage and sharing, an IT knowledge base, and the Ultimaker 3D Printing Academy e-learning platform

Find out more

Essential Features

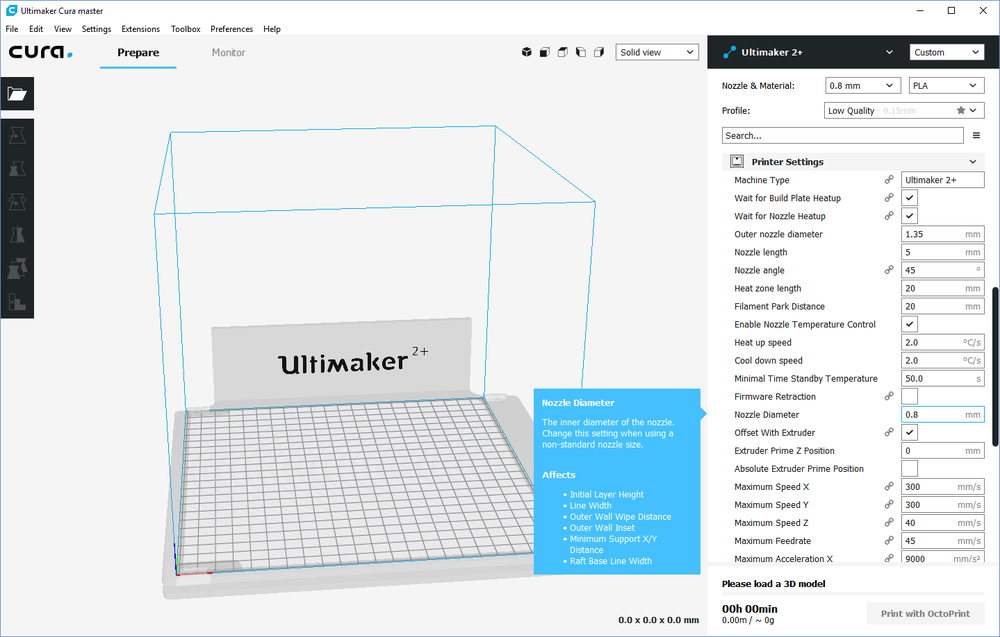

Sliced your way

With a simple click or through 400 customizable settings, prepare files for 3D printing in the way that works for you

Continuous security improvements

Each release of Ultimaker Cura Enterprise is independently scanned, tested, and analyzed for vulnerabilities. We publish a summary of that report and we commit to continuously improving security.

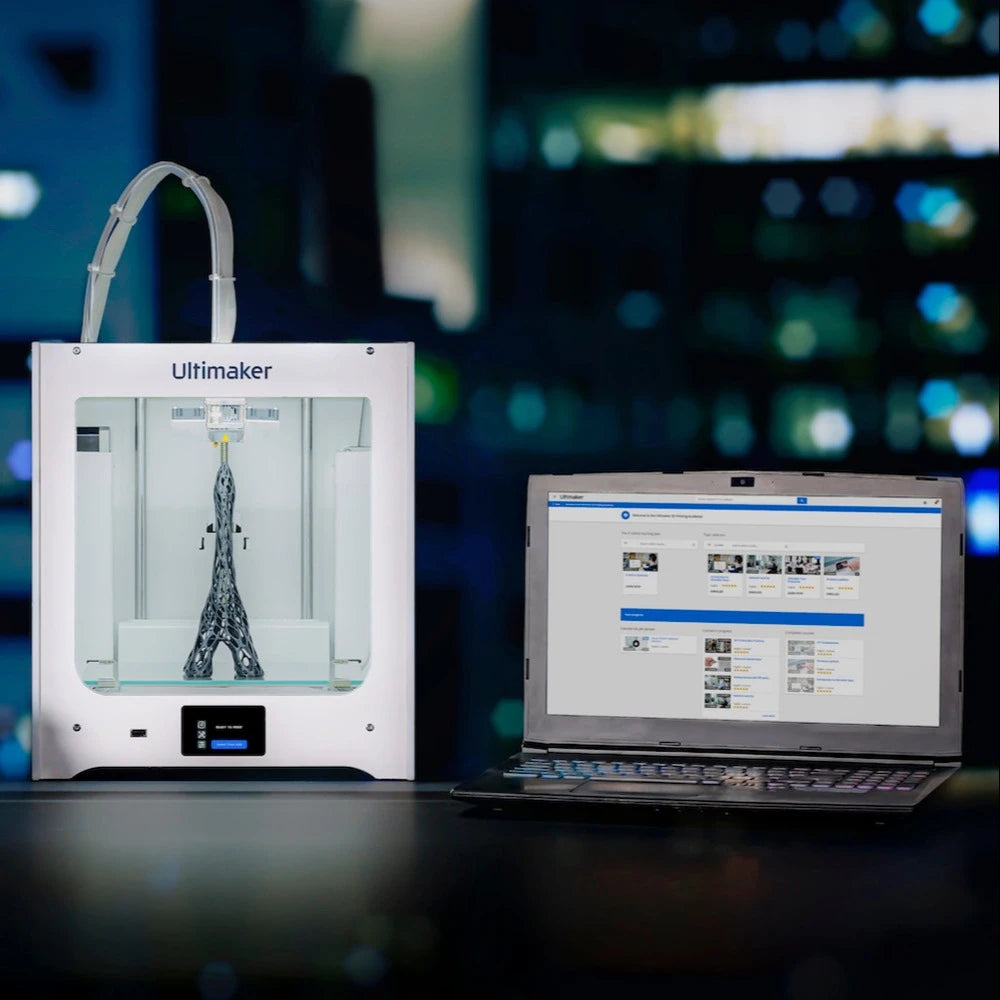

Start 3D printing from anywhere in the world

Whether you're working from home or in the office, send secure print jobs via the cloud to Ultimaker 3D printers on your network. Then stay informed of print progress thanks to remote device monitoring.

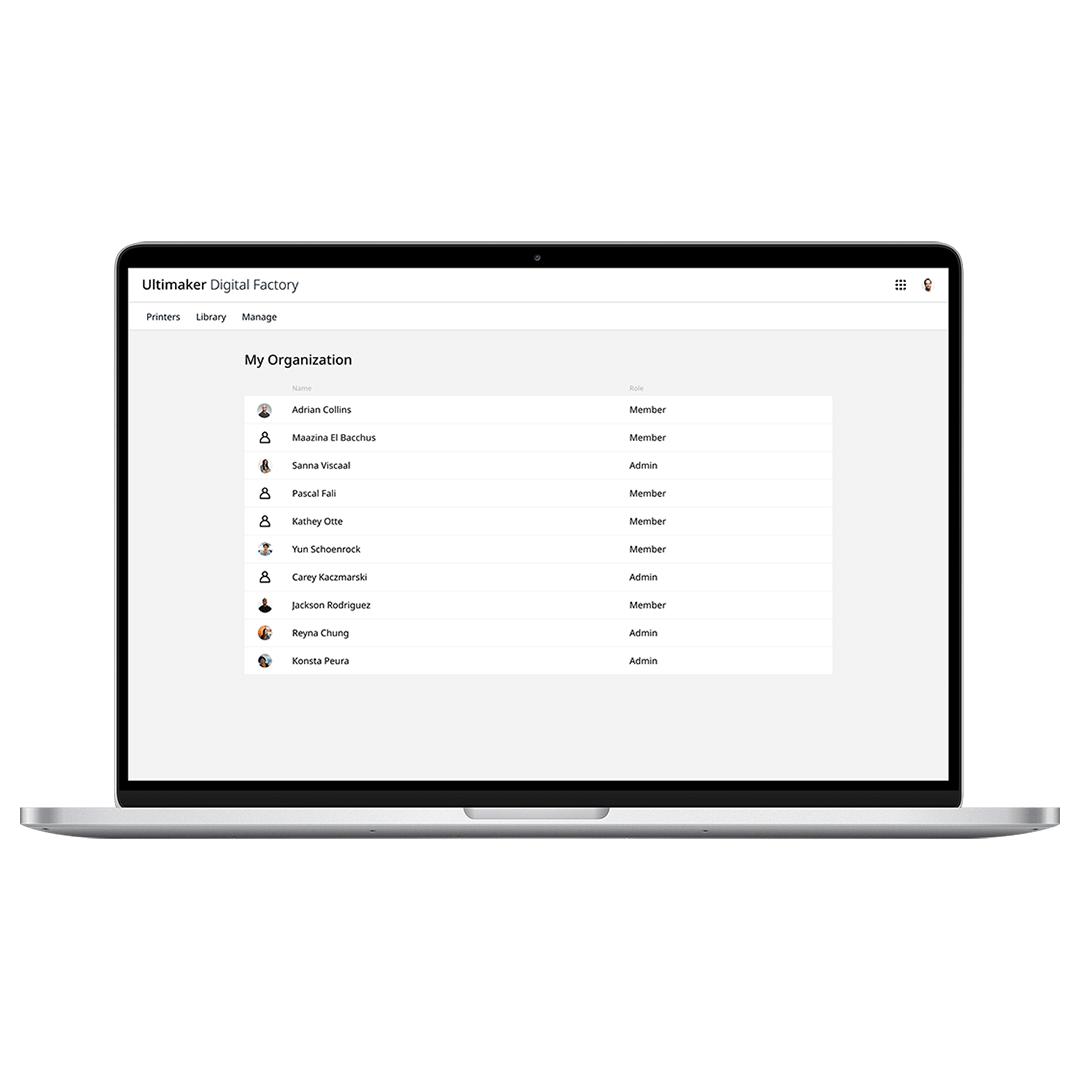

Manage access across your business

When it comes to who can 3D print – you decide. Via the organization management page, the Ultimaker software platform lets admins invite users, give them admin rights, or remove 3D printing access entirely.

Cloud-hosted, globally accessible

A central Digital Library of internally developed applications means your designers and engineers can access the parts and tools they need, wherever they are

Direct software support

Reduce downtime, reduce disruptions – direct software support means you're back on track as soon as possible

Role-based courses put you in control

Associate e-learning courses for application engineers and 3D printing operator ensure you start off on the right foot

Hardware Features

Bigger build volume

A build volume of 330 x 240 x 300 mm (13 x 9.4 x 11.8 inches) gives you more freedom to produce larger designs or print multiple parts on one build plate. So you can meet demand with maximum efficiency, with a 3D printer that fits comfortably on your desk.

Perfect build plate adhesion – without the hassle

Multi-point probing with the print head's capacitive sensor compensates for tiny variations in build plate topography, resulting in an always-perfect first layer.

Say goodbye to bed adhesion issues

Advanced active leveling with the Ultimaker S5 means you can start your print and stay focused on your work. The print head's capacitive sensor automatically detects microscopic variations in the build area topography and compensates with Z-axis offsets.

Start 3D printing in 30 minutes

Anyone can 3D print using the Ultimaker S5. Our machines are so easy to use that, after a 30-minute introduction, customers feel confident to start 3D printing their own designs – with no need for a dedicated operator.

Save time with tested, predefined print settings

Take advantage of tested and predefined print settings with Ultimaker Cura. These settings not only include Ultimaker's own materials, but also a growing library of print profiles from leading materials brands, available via Ultimaker Marketplace.

A perfect fit for your desktop

The Ultimaker S5 fits easily on any desktop. Its internal design allows both nozzles to reach the whole build plate. That wider nozzle coverage means that no space is wasted and offers an increased build-volume-to-size ratio.

3D printing materials. The choice is yours

The Ultimaker S5 is compatible with almost any 2.85 mm filament. 3D print with third-party materials as easily as Ultimaker filament, with predefined print settings on Ultimaker Marketplace – including carbon fiber-reinforced composites for high-strength parts.

Seamless integration with your in-house workflow

From CAD design to printed part, Ultimaker S5, Ultimaker materials, and Ultimaker Cura provide an end-to-end solution that easily improves and integrates with your in-house production workflow.

Professional results, affordable price

We've done the math. And with its low annual cost of ownership, the Ultimaker S5 offers an affordable entry to professional 3D printing, making ROI easy and fast to achieve.

Technical specifications

| Build volume | 330 x 240 x 300 mm (13 x 9.4 x 11.8 inches) |

|---|---|

| Assembled dimensions | 495 x 585 x 780 mm (19.5 x 23 x 30.7 inches) |

| Print technology | Fused filament fabrication (FFF) |

| Weight | 20.6 kg (45.4 lbs) |

| Maximum power output | 500 W |

| Layer resolution | 0.25 mm nozzle: 150 - 60 micron 0.4 mm nozzle: 200 - 20 micron 0.6 mm nozzle: 300 - 20 micron 0.8 mm nozzle: 600 - 20 micron |

|---|---|

| XYZ resolution | 6.9, 6.9, 2.5 micron |

| Feeder type | Dual-geared feeder, reinforced for composite materials |

| Display | 4.7-inch (11.9 cm) color touchscreen |

| Print core replacement | Swappable print cores |

| Print head | Dual extrusion print head with an auto-nozzle lifting system and swappable print cores |

| Nozzle diameters | 0.25 mm, 0.4 mm, 0.6 mm, 0.8 mm |

| Build speed | < 24 mm³/s |

|---|---|

| Nozzle temperature | 180 - 280 °C |

| Nozzle heat-up time | < 2 minutes |

| Operating Sound | < 50 dBA |

| Build plate leveling | Advanced active leveling |

| Build plate | 20 - 140 °C heated glass build plate |

| Build plate heat-up time | < 4 minutes (from 20 to 60 °C) |

| Operating ambient temperature | 15 - 32 °C (59 - 90 °F) |

| Non-operating temperature | 0 - 32 °C (32 - 90 °F) |

| Supplied free software | Ultimaker Cura – print preparation software Ultimaker Connect – printer management software |

|---|---|

| Cloud support | Ultimaker Cloud |

| Support OS | MacOS, Windows, and Linux |

| Plugin integration | SolidWorks, Siemens NX, Autodesk Inventor |

| Support file types | Ultimaker Cura: STL, OBJ, X3D, 3MF, BMP, GIF, JPG, PNG Printable formats: G, GCODE, GCODE.gz, UFP |

| File transfer | Wi-Fi, LAN, USB |

| Certification | CE, FCC, VPAT, RoHS, REACH, CB, BIS, KC, PSE, RCM, SRRC, MIC, NCC, Safe unattended professional use |

|---|---|

| Documentation | MSDS download VPAT download CE download |

| Training | Our courses are designed to take you from complete novice to an expert user of 3D Printers, 3D Scanners, Software and materials. Being able to install, operate and solve technical issues without the need for a technician. Training is available online or via our dedicated technical team for more information see our training options. | |

|---|---|---|

| 3DGBIRE 6 month warranty and lifetime support | All the parts, except the hot end, come with a 6 month warranty. Ultimaker also offers lifetime support through email and phone. There's also an awesome community with plenty of knowledge to help you out when you're in need. | |

| Lifetime support | Expert technical support via email, phone, or from our global community is available to you for the lifetime of your printer. How can we help you?. | |

| Extended support | Online resources, extensive manuals (in multiple languages), material technical and safety data sheets (in multiple languages), a detailed knowledge base, and much more. | |

| Ultimaker Community | It's an active community of experts who are full of useful tips and tricks, are always on hand for troubleshooting and collectively create a great networking platform. In fact, some of our key product upgrades and ideas were conceived in this very community. So when you add it all up, it's an open source experience you need to be a part of and don't want to miss out on! Join now. |

Additional Products

Ultimaker S5 Air Manager

The Ultimaker S5 Air Manager provides a closed, inside-out airflow throughout the printing process. This leads to a better-controlled environment inside the build chamber and filters up to 95% of ultrafine particles created while printing. The result? A safer work environment and peace of mind when printing with a wider range of materials with an Ultimaker S5.

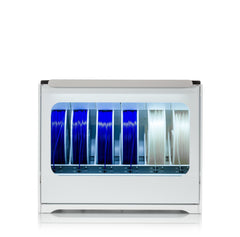

Ultimaker S5 Material Station

The Ultimaker S5 Material Station is a humidity-controlled chamber with six material spools that can be loaded in any order with up to 4.5 kg of material. Each bay features automatic material switching, composite-ready feeder wheels, and filament flow sensors. Now you can achieve increased productivity, easier operation, and higher-quality production.

Official Pro Training From UK Experts for Ultimaker 3D Printers

Our training packages will take you from a complete novice to a 3D printing expert. Don't get left behind

Ultimaker Training

Our courses are designed to take you from complete novice to an expert user of 3D Printers, 3D Scanners, Software and materials. Being able to install, operate and solve technical issues without the need for a technician.

View OptionsCase Studies

Ensuring production continuity with 3D printing

With over 150 breweries around the world, Heineken is one of the largest global producers of beer. One brewery in Seville, Spain, produces famous brands such as Cruzcampo, Desperados, Heineken, and Amstel. The beer is brewed, packed, and then shipped throughout Spain and beyond. Packaging Manager, Juan Padilla González has implemented 3D printing to increase uptime and efficiency at the Seville brewery

Read HereBook a Live Demonstration

Why 3DGBIRE?

3D Printers and Accessories

As one of the largest 3D printing distributors in the UK & Ireland, we sell some of the most advanced printers from leading industry manufacturers. Not only do we have top-of-the-range 3D printers, we also supply cleaning kits, filaments and accessories etc…

Buy NowSpare parts

We stock all spare parts and pieces for a range of advanced 3D Printers. If there is a part or piece you can not find on our website, don't hesitate to contact us, as we most likely will have it in stock...

Buy Now

Training

Our courses are designed to take you from complete novice to an expert user of 3D Printers, 3D Scanners, Software and materials. Being able to install, operate and solve technical issues without the need for a technician...

Click HereSupport

Whatever your problem, big or small, we are always ready to help as we have a dedicated support team to help you install, print and keep your machine in tip-top shape…

Contact Us