Combining the prowess of 3D printing and 3D forming opens a gateway to manufacturing possibilities previously unexplored. 3D printing excels in creating intricate prototypes and complex geometries with precision, offering the flexibility to iterate designs rapidly. Leveraging these printed models in tandem with 3D forming techniques, such as vacuum or pressure forming, extends the horizon of production.

Pressure forming performance

Replicate intricate structures on the sub-micron level for perfectly produced parts.

No layers, no de-lamination. Strong, isotropic parts formed from the desktop.

Work with a wide range of pure, factory-grade materials.

Real world examples

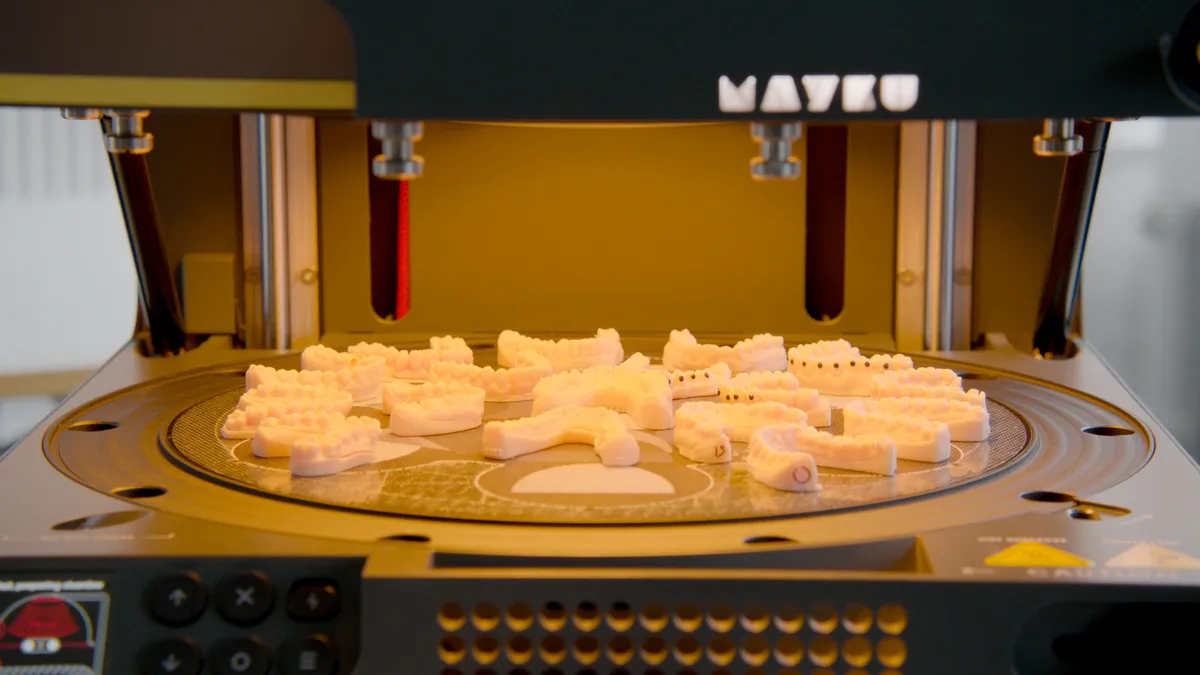

George Szekely Dental Lab increases productivity with the Mayku Multiplier

George Szekely Dental Laboratory, established in 1968, is a dental prosthetics facility owned by Janine Cerbu and her business partner Amha Selassie.

Industrial food molds

Material: Food-safe PETG

Benefit: Rapid production of food-safe molds with reduced lead times and costs

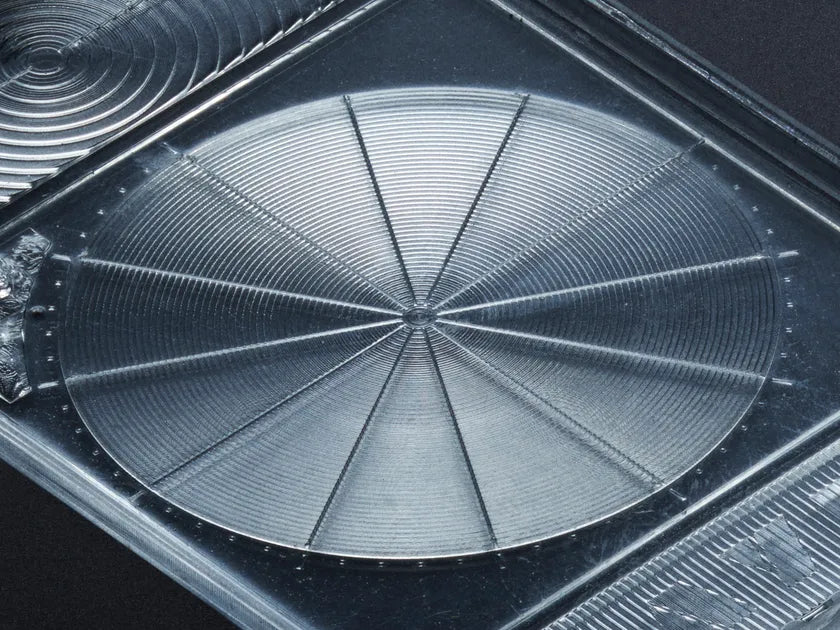

Transparent light lens

Material: PMMA

Benefit: Small batch of Transparent, UV resistant with high impact strength with no tooling investment

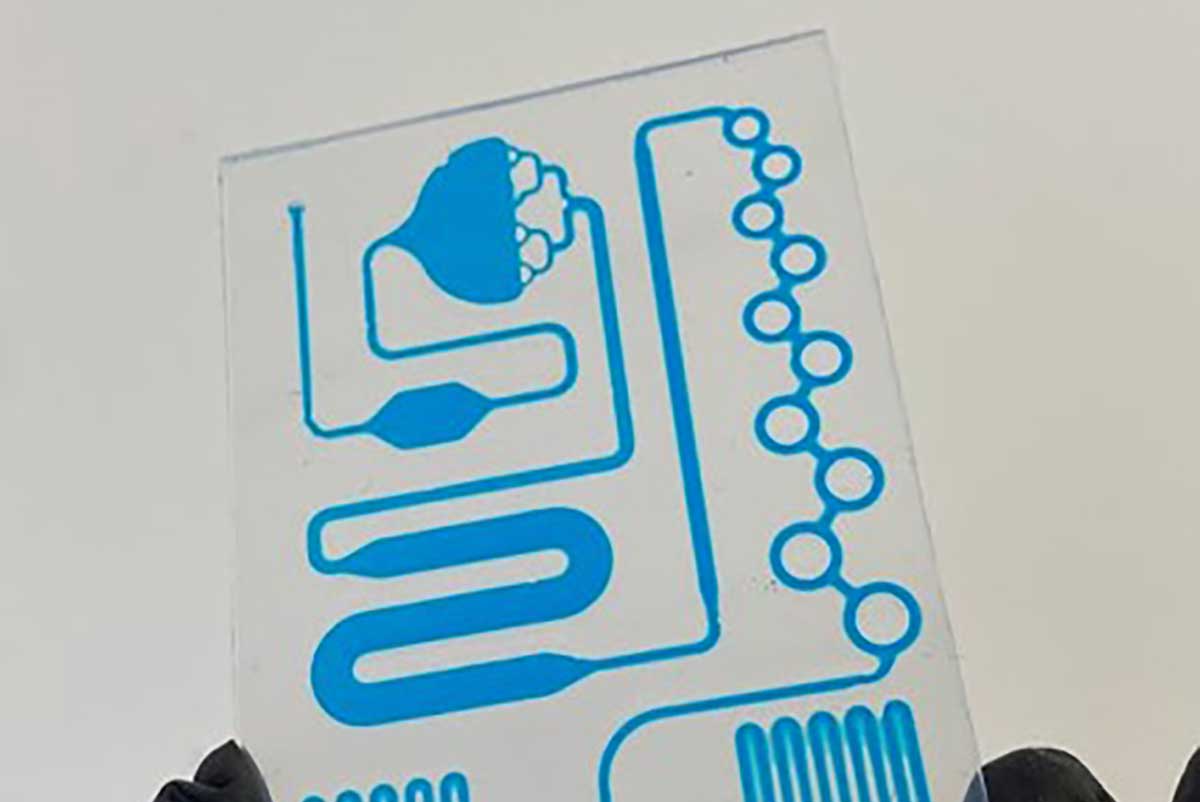

Small batch microfluidics chips

Material: EVA and pressure-sensitive tape

Benefit: Reduce tooling investment risk, validate final production materials

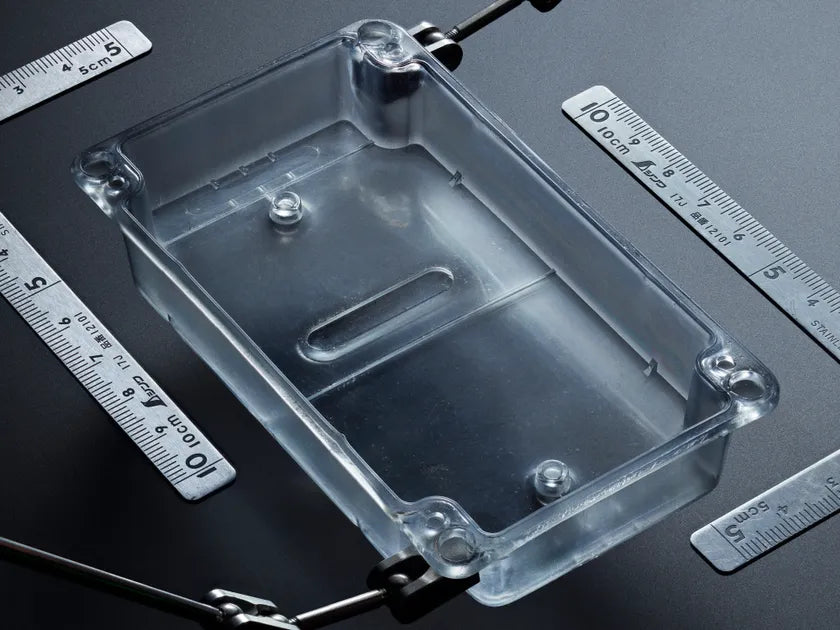

Prototyping of consumer goods packaging

Material: PETG

Benefit: Rapid iteration and tolerance checking of prototypes in final materials, decreasing time to market

Protective coverings for production line machine

Material: 4mm ABS

Benefit: Maintain production uptime, reduced parts costs, reduced lead times

The Multiplier is not a vacuum former

Unlike traditional forming, our patented pressure forming method applies consistent pressure across the entire mold, resulting in flawless reproduction of even the most intricate designs.

Vacuum Formed

Pressure Formed

How it works

Precisely control heat and pressure to create flawless highly detailed parts with production-grade thermoplastics

1. Create your template

Use a 3D printer, CNC milling machine or other process to make a template to form over.

2. Select your material

Choose a material profile from the machine’s menu or use custom mode to create a custom profile of your own.

3. Insert your template

Wait whilst the Multiplier heats your material precisely, the auto-leveling system will keep it level whilst bringing it to the forming temperature.

4. Form your part

Close the machine and the Multiplier releases up to 4 atmospheres of pressure, exerting up to 5 tonnes of force on your material, pushing it into every detail of your template

Reducing Plate: Save material and get a perfect form

The Multiplier Reducing Plate condenses the forming area of the Multiplier down to A4 or US letter format.

- Reduce material waste when forming smaller parts

- Work with thicker materials over 5mm

- Work with thinner materials as low as 100 microns

- Use more readily available materials in A4 or US Letter size

- Decrease webbing on tall parts by reducing the amount of material that would "bunch" around a given part

Key specifications

60 psi / 4 bar

Forming pressure

440°F / 225°C

Maximum temperature

15" / 380mm

Forming area

6.5" / 160mm

Draw height

<1µm

Resolution

Features

Industrial heat & pressure for ultra-precision

Capture sub-micron details and achieve intricate designs with thick and thin materials. Produce parts with an accurate surface finish that replicates the sub-micron features of your template. Create isotropic parts, ensuring both structural integrity and aesthetic consistency.

Precision control for unrivaled forming quality

The Multiplier's auto-leveling system ensures a stable and consistent material surface while heating. The system allows for precise temperature control, enabling materials to reach their forming temperature without undergoing deformation or stretching. This allows for increased definition of the part, as sheets can be safely brought to higher temperatures than any other thermoformer for more detailed forming. The result is a reliable and precise thermoforming process suitable for a wide variety of applications.

Tuned perfectly to your material

Our user-friendly interface allows you to create, save, and edit custom forming profiles for any compatible thermoformable material. This enables you to obtain consistent, high-quality results with your own materials. You can precisely control temperature and pressure, allowing you to adjust the level of detail to achieve your desired finish.

Scalable prototyping and production

Fast cycle times of two to thirty minutes, depending on the material type. No matter how large or how many templates you place on the bed, the forming cycle remains constant, giving you consistent time-per-part production.

User-friendly operation for all skill levels

The Multiplier Pressure Former features an intuitive user interface designed for ease of use right out of the box. The interface is built to guide users in optimizing machine performance, ensuring consistent and reliable results. It is suitable for individuals with various backgrounds and skill levels, and our expert application engineers are always on hand to assist with any specialized projects.

Streamline your workflow in-house

Designed to fit on your bench-top, the Multiplier pressure former will always be within reach, enabling you to use it exactly when you need it. Eliminate the delays and uncertainties associated with outsourcing by taking control of the prototyping and production process yourself. Iterate faster, accelerate your learning curve, and speed up your journey from concept to production.

Reliability and precision in every cycle

Engineered for consistent performance, our machine ensures high repeatability and replicability every time you operate it. Whether you're running a single part or multiple batches, you can count on uniformity in all the parts produced.

Dental Applications

Make more, faster

Form up to 19 appliances in one pull with large 428mm diameter blanks, freeing up time for you and the team to focus on other crucial tasks (like lunch).

Avoid the droop

The innovative built-in temperature sensor and auto-leveling system keep your material perfectly level while it heats. This eliminates drooping, which reduces thinning and allows for consistent, repeatable results across forms and the technicians making them.

It’s a material world

Combined with one of the reducing plate accessories, the Multiplier can handle all standard sizes of thermoforming materials. It will work with 120mm round, 125mm round, 428mm round, and A4 dental thermoforming blanks from 0.1-5mm thicknesses without breaking a sweat.

Unique profiles, infinitely customisable

Material profiles arrive pre-installed on the machine. Customize, edit, and save your favorites to your desired fit using the simple-to-use interface. Once a profile has been created, you can then save it and replay it back in one click - giving you consistent, reliable products for every batch.

Updateable firmware

Connect your machine to Wi-Fi for over-the-air firmware updates, the latest material profiles, and new machine functionality, so you can stay on top of your game.

Internal compressor

No need for an external air supply; the Multiplier has an internal compressor (and air out port) to ensure a completely clean air supply wherever you want to place it.

A suite of industrial grade thermoforming materials

Technical specifications

| Height | 420mm |

|---|---|

| Length | 585mm (with handles) |

| Width | 515mm |

| Forming bed | 400mm (L) × 400mm (W) x 160mm (H) |

| Weight | 68kg (boxed) |

| Power Supply Input | 110 240V, 12A/6A (Single Phase) |

|---|---|

| Max Power | 1500W |

| Maximum pressure | 4.1 bar/60 psi (Dome), 12 Bar/175 psi (Tank) |

| Frequency | 2.4GHz |

| LCD Resolution | 720x720 |

| Operating / storage temperature | +5 to +40°C |

| Connectivity | WiFi |

| Forming area | 400mm (W) x 160mm (H) |

|---|---|

| Max template volume | 3500cm3 / 214in3 |

Book a Live Demonstration

Why 3DGBIRE?

3D Printers and Accessories

As one of the largest 3D printing distributors in the UK & Ireland, we sell some of the most advanced printers from leading industry manufacturers. Not only do we have top-of-the-range 3D printers, we also supply cleaning kits, filaments and accessories etc…

Buy NowSpare parts

We stock all spare parts and pieces for a range of advanced 3D Printers. If there is a part or piece you can not find on our website, don't hesitate to contact us, as we most likely will have it in stock...

Buy Now

Training

Our courses are designed to take you from complete novice to an expert user of 3D Printers, 3D Scanners, Software and materials. Being able to install, operate and solve technical issues without the need for a technician...

Click HereSupport

Whatever your problem, big or small, we are always ready to help as we have a dedicated support team to help you install, print and keep your machine in tip-top shape…

Contact Us