- Description

- Quality

- Tips & tricks

- Downloads

Ultrafuse‚® PA6 GF30 contains 30% of special glass fibers that aredesigned for filament making and 3D printing so. PA6 GF30 has a reduced warping compared to neat PA6 which makes Ultrafuse‚® PA6 GF30 with its excellent layer adhesion and its compatibility with the watersoluble Ultrafuse‚® BVOH the right solution for industrial parts printable on any standard FFF printer. With its high wear and chemical‚ resistanceand the high stiffness and strength, Ultrafuse‚® PA6 GF30 is perfect forvarious applications in transportation or industrial tooling for example.

Benefits at a glance

‚· Very high stiffness and strength ‚· Good chemical resistance ‚· Resistance to UV light ‚· High wear resistance ‚· Excellent layer adhesion ‚· Works with BVOHWe select the best raw materials available from renowned suppliers.

Dedicated people, highest standards.

Production on our state-of-the-art computer controlled machinery guarantees a truly consistent filament, also between colors and batches.

It will perform as expected, every time.

All our products are 100% traceable to the source.

Nozzle Temperature; 240-280 ‚°C

Build Chamber Temperature; €š‚“

Bed Temperature; passively heated, closed chamber

Bed modification; glass

Drying Procedure; Dry the filament at 100‚°C for at least 5 hours

Support Materials; BVOH

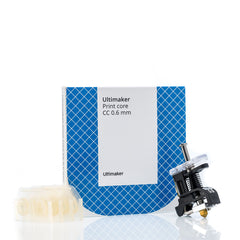

Nozzle Diamater; ‚°¥ 0.6 mm

Print Speed; 30-60 mm/sec