Reducing plastic waste through prototyping highly detailed parts

Reducing plastic usage in mass manufacturing is one of the most critical issues of our time. Solutions to this challenge begin at the prototyping stage, where design decisions are made that will resonate throughout the product's lifetime when it goes to market.

Morrama is a leading product design agency based in London, UK, with a strong focus on sustainable, thoughtful, and beautiful designs for world-leading brands and startups.

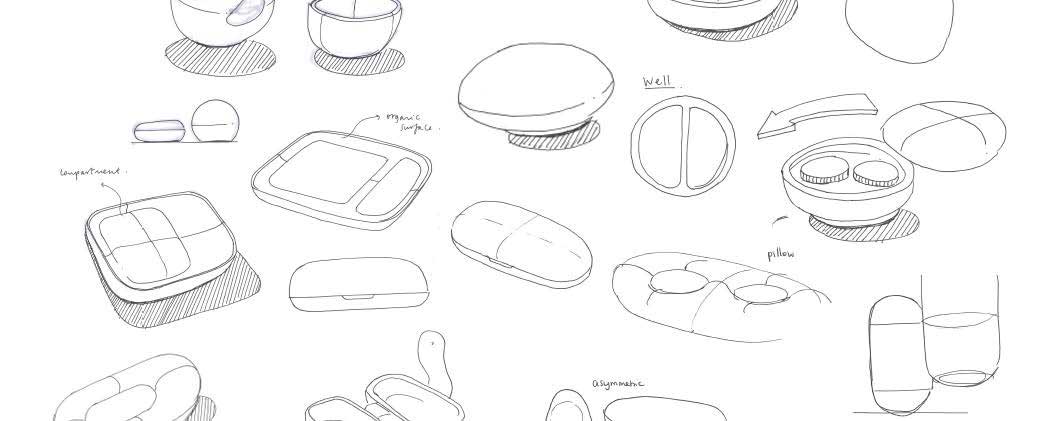

Morrama was contracted by the startup ‘Hard’ to develop a new product design that reduces the amount of plastic in monthly contact lens cases, of which millions are produced and disposed of each year.

Lucy, a design engineer at Morrama responsible for developing the prototypes, utilized the wide material selection of the Multiplier and its high accuracy to develop prototypes of a new type of contact lens case.

The Challenge: Reducing plastic waste in monthly contact lens cases

Monthly contact lens cases can accumulate bacteria that may pose a danger to users' eye health. Therefore, the current solution involves disposing of the plastic case on a monthly or bi-weekly basis, resulting in a significant amount of plastic waste.

Material selection is critical here, as the material must protect the contact lens while remaining inert to avoid contaminating the contact lens solution.

Typically, the entire case is made from a single, larger piece of plastic, resulting in substantial monthly material waste.

Morrama aimed to significantly reduce the plastic waste in the product while retaining the essential material attributes required for proper product functionality. The key component in achieving this was the thin-gauge 'cup' that would house the contact lens in its solution.

Morrama decided on a strategy to develop a small, thin-gauge cup and place it inside a more robust, long-lasting case to protect the internal cup and contact lens.

For this strategy to succeed, they needed to test the fine tolerances of the material they were using to ensure a perfect fit inside the prototype outer casing. This precision would translate well to a mass production process like injection molding later in the development cycle.

However, Morrama encountered difficulties when attempting to prototype thin- gauge materials using rapid prototyping technologies such as 3D printing or CNC, as the end part was extremely fragile and unsuitable for form and fitment testing. They also needed to prototype the parts in transparent material, something that additive manufacturing and CNC does not perform well at. They also explored a medical-grade 3D printing facility, but the costs proved to be exceedingly high.

Initiating injection molding tooling prematurely is expensive and can lead to issues later in the development process but they needed a prototype part in 0.5mm* and they needed it quickly and at a high tolerance.

The Solution: Developing an innovative new case and cup concept rapidly

Morrama opted to use the Multiplier to prototype the thin-gauge cup by 3D printing a male mold on a FormLabs SLA 3D printer using high-temperature resin. They sourced a 0.5mm PETG sheet online from a medically certified sheet supplier.

They collaborated closely with Mayku's in-house application engineers to identify the correct material and develop the most optimal design for high-pressure thermoforming.

This approach allowed them to test the fit, tolerance, and material functionality, creating and assessing multiple prototypes before each iteration.

It also enabled them to prototype parts in optically clear PETG material, a characteristic difficult to achieve with CNC or additive manufacturing methods. This allowed for a prototype more closely resembling the final production product.

By quickly obtaining functional parts without investing in expensive tooling, they significantly reduced both time and costs in the development cycle, helping them bring the product to market faster and more cost-effectively.

The Results

With functional parts in hand swiftly, Morrama was able to shorten the product's development cycle, enabling their client to enter the market more rapidly while avoiding costly delays down the line.

They successfully reduced the amount of plastic waste in the end product by 90%.

"The multiplier has been an invaluable tool in quickly & cost-effectively validating the contact lens case inserts. We were able to rapidly test the function, and user interaction ahead of committing to tooling. Another benefit of this technology is that we were able to produce a cost- effective, look-like prototype that was used to demonstrate the product to potential investors."

Lucy Williams, Morrama Design Engineer