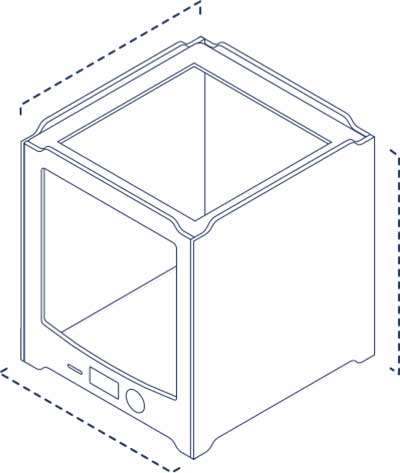

PRINTER AND PRINTING PROPERTIES

Assembly type: Pre-assembled

The Ultimaker 2+ is an out of the box experience and immediately ready to use, as it comes pre-assembled. If you’re looking for a DIY kit that you need to assemble yourself, check out our Ultimaker Original+

Layer Resolution0.25 mm nozzle: 150 to 60 micron

0.40 mm nozzle: 200 to 20 micron

0.60 mm nozzle: 400 to 20 micron

0.80 mm nozzle: 600 to 20 micron

A micron is the measurement used to define the thickness of a 3D printed layer. 20 microns is 0.02 mm thick. 600 microns is 0.60 mm. Thinner layers are used for high detailed prints, thicker layers are great for fast prototypes. Build plate 50˚ to 100˚ C heated glass build plate Due to the 50˚ to 100˚ C heated glass build plate you’re able to use a much larger selection of filaments for your prints. To clean the plate simply open the clamps and remove it.

Build plate leveling - Assisted leveling processIt’s really easy to level the build plate using the printer’s assisted leveling process. The print head automatically moves to the back of the build plate, after which the user turns the matching knob and uses the Ultimaker calibration card to set the right height. The print head will continue to the front left side, and then the front right side. This process is repeated once, after that you’ll have a perfectly leveled bed which will stay leveled for a really long time thanks to the sturdy build of the build plate. Print technology - Fused Filament Fabrication (FFF) This is the process of depositing layers of filament, one on top of the other, to build up shapes and models. Also known as additive manufacturing technology, it’s the process used by all Ultimaker 3D printers.

Print head - Swappable nozzleThanks to the swappable nozzle, you can quickly switch between different nozzles. The standard is 0.4 mm, but you also have the option to use a 0.25 mm nozzle for detailed prints or a 0.6 mm/0.8 mm for faster prints. The new fancaps ensure the airflow is aimed perfectly below the nozzle and equally from both sides and the new Sunon fans are more silent than ever. The heater cartridge is now 35W which improves heat up times and print speeds. The PTFE isolator is made from TFM, which has a longer life span. We’ve removed the spring and implemented a spacer, this puts less pressure on the PTFE isolator which also expands its life span. We’re using a new sensitive PT-100 temperature sensor, it provides accurate readings so you can tweak the settings with precision.

Feeder type - Geared feederThe innovative feeder allows you to easily swap filament and choose the correct pressure for your filament. For example with a softer filament you’ll need to choose a lower pressure. Such control increases the success rate of your prints. It also features a lever, when raised, you can manually insert or remove filament.