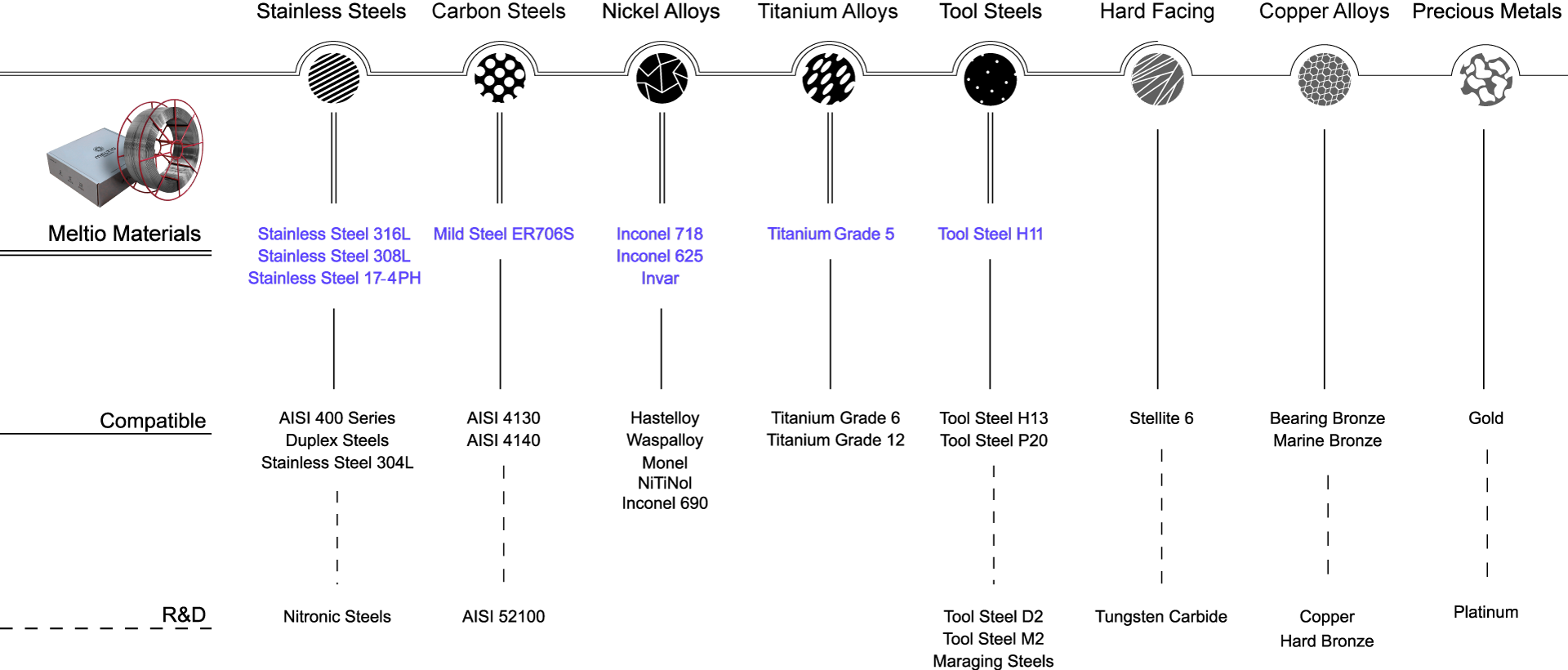

Meltio Materials

Enhance your application with Meltio's Laser Metal Deposition process, renowned for delivering outstanding material mechanical properties with both single wire and dual wire options. Optimise your welding experience by selecting from our range of options: unlimited third-party commodity materials or Meltio Wire Materials, rigorously qualified to ensure superior user satisfaction.

View Meltio MaterialsFirst-Time-Right with Meltio Materials

Meltio Material Range

Meltio Stainless Steel 308L Wire spool 15kg, Ø1mm

All-round Stainless steel with adequate corrosion resistance and good mechanical properties. Technical Information Diameter: 1 mm Weight: 15 kg Volume: 1875 cm³ Density: 8.0 g/cm³ Spool type: BS300 Download Technnical...

Meltio Titanium 64 Wire spool 7.5kg, Ø1mm

High strength Alpha+Beta alloy with excellent fracture toughness, corrosion resistance and biocompatibility. Widely used in aerospace, marine, chemical and biomedical industries Diameter: 1 mm Weight: 7,5 kg Volume: 1704 cm³...

Meltio Nickel 718 Wire spool 15kg, Ø1mm

High strength nickel-super alloy with large working temperature range. Highly resistant against cracking while protecting well against corrosion. Technical Information Diameter: 1 mm Weight: 15 kg Volume: 1829 cm³ Density:...

Meltio Mild Steel ER70S Wire spool 15kg, Ø1mm

All-round Stainless steel with adequate corrosion resistance and good mechanical properties. Technical Information Diameter: 1 mm Weight: 15 kg Volume: 1875 cm³ Density: 8.0 g/cm³ Spool type: BS300 Data Sheets...

Meltio Nickel 625 Wire spool 15kg, Ø1mm

A Ni-based superalloy with excellent mechanical properties at a wide range of temperatures. Among superalloys, Ni625 excels for its weldability, making it an ideal choice for cladding or repair of...

Meltio Tool Steel H11 Wire spool 15kg, Ø1mm

A chromium-based steel alloy, it’s one of the most commonly used tool steels, thanks to its outstanding impact toughness. H11 is widely used for hot tooling applications, in the manufacturing...

Meltio Stainless Steel 17-4PH Wire spool 15kg, Ø1mm

A martensitic precipitation hardened stainless steel capable of achieving high hardness while offering excellent corrosion resistance. It is widely employed in the oil & gas, aerospace, energy, and defense industries....

Meltio Stainless Steel 316L Wire spool 15kg, Ø1mm

Highly corrosion-resistant grade of austenitic stainless steel with great mechanical properties. Ideal for marine and chemical applications. Stainless Steel 316L is an austenitic steel with excellent durability, good biocompatibility and...

Single and Dual Metal 3D Printing

Achieve exceptional mechanics decreased thermal stress and near isotropic properties. Available in welding wire between 0.8 and 1.2 mm in diameter.

Single Wire

The cornerstone of the 3D printing process revolves around wire, recognised as the safest, cleanest, and most user-friendly metal feedstock available.

Dual Wire

Integrate various metal materials seamlessly within a single part. Our automated wire-switching process ensures swift and pristine transitions, enabling efficient production without compromise.

>99.998 % Densification

Meltio's Laser Metal Deposition (LMD) process yields fully dense parts boasting superior microstructure, achieving an exceptional densification rate of up to 99.998%.

Layer Height

Meltio offers layer heights from 0.6 to 1.2 mm, with surface roughness that can outperform powder-based methods in certain conditions.

Unlimited Third-party Material Choice

| Stainless Steels: | Excellent strength and corrosion resistance. |

|---|---|

| Mild Steels: | Cheap and ductile, with unparalleled machinability and weldability. |

| Carbon Steels: | High impact strength, retain hardness at high temperatures. |

| Titanium Alloys: | Highest strength to weight ratio and corrosion resistance. |

| Nickel Alloys: | High versatility, outstanding heat and corrosion resistance. |

| Copper & Aluminum: | Under Development. |

Meltio mild steel ER705

Mild steel, boasting sufficient mechanical strength and remarkable ductility, is effortlessly weldable and machinable.

Meltio Steel H11

A chromium-based steel alloy, it stands as one of the most prevalent tool steels, renowned for its exceptional impact toughness.

Meltio Invar

This alloy, named for its ultra-low coefficient of thermal expansion (-250°C to about 200°C), is perfect for precision measuring and cryogenic uses.

Meltio Titanium 64

High-strength Alpha+Beta alloy offers excellent fracture toughness, corrosion resistance, and biocompatibility, widely utilized in aerospace, marine, chemical, and biomedical industries.

Meltio Nickel 718

Durable nickel super alloy boasting high strength and a broad operating temperature range. Exhibits exceptional resistance to both cracking and corrosion.

Meltio Nickel 625

A nickel-based superalloy renowned for its superb mechanical properties across a broad temperature spectrum. It stands as an optimal selection for cladding or repair applications.

Meltio Horizon Software

Meltio Horizon is an exclusive slicing software designed to provide a fully personalized customer experience for our plug-and-play metal 3D printer. The Meltio M450 comes with its distinctive features, along with custom-developed Meltio print and material profiles.

Unlimited Third-party Material Choice

Choose the ideal welding wire for your applications

Stainless Steels

Excellent strength and corrosion resistance.

Mild Steels

Cheap and ductile, with unparalleled machinability and weldability.

Carbon Steels

High impact strength, retain hardness at high temperatures.

Titanium

Highest strength to weight ratio and corrosion resistance.

Inconel

High versatility, outstanding heat and corrosion resistance.

Copper

Under Development.

Book a Consultation

We're here to answer your questions

Implementing a new technology can be a painful experience, slowing down your core business and not returning results immediately.

Let our team take your headaches away, our knowledge of integrating 3D printing into different industries and applications is second to none.

We’d love to hear about your project and help you find the right solution.