HP Jet Fusion 5200 Series

Industrial 3D Printing Solution

Drive new growth and expand into volume production with HP’s robust, manufacturing-ready industrial 3D printers.

Request a Quote Book a ConsultationHP Jet Fusion 5200 Series 3D Printer

Industrial 3D Printing Solution

Drive new growth and expand into volume production with HP’s robust, manufacturing-ready industrial 3D printers.

Available to order Now!

Expand and scale into volume production with HP industrial 3D printers

Enhanced manufacturing predictability

Breakthrough productivity and automation

Expand into new applications and markets

Explore the complete HP Jet Fusion 5200 Series 3D Printing Solution

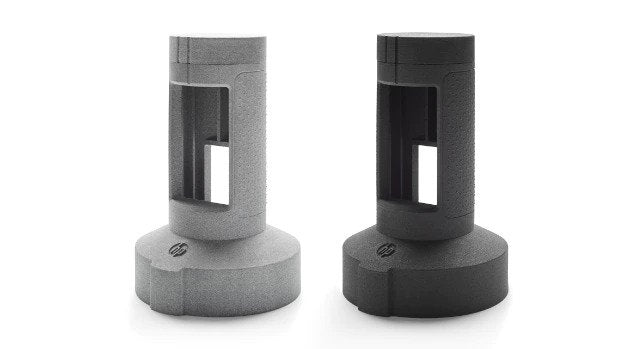

HP 3D High Reusability PP5 enabled by BASF

Chemical resistant,6 weldable, low moisture absorption, functional parts

HP 3D High Reusability PA 118

Ductile,9 quality parts

Data courtesy7

HP 3D High Reusability PA 1211

Strong, low cost,12 quality parts

Data courtesy10

HP 3D High Reusability PA 12 GB14

Stiff, dimensionally stable, quality parts

Data courtesy13

BASF Ultrasint® TPU01

Flexible, functional parts.

Data courtesy15

HP Jet Fusion 5200 Series 3D Automatic Unpacking Station

Achieve consistent unpacking results through an automatic process with an industrial-grade solution.

Learn

HP Jet Fusion 5200 Series 3D Automatic Unpacking Station

Achieve consistent unpacking results through an automatic process with an industrial-grade solution.

Learn

Autodesk® Netfabb® with HP Workspace

Provides advanced software for the additive manufacturing of production quality parts.

Learn

HP Build Processor

The industry standard software for professional 3D Printing, to unlock the full potential to manage every step in your production process.

Learn

Siemens NX AM

Combine design, optimization, simulation, preparation of print jobs, and inspection processes all in a single managed environment and with minimal steps.

Learn

HP Jet Fusion 5200 3D Natural Cooling Unit

Designed to remove and cool each build naturally, thereby enabling continuous production.

Hovmand Forklift 5200

HP recommended accessory to remove and place the HP Jet Fusion 5200 3D Natural Cooling Unit from the processing station.

Learn

HP 3D Solution Services

Explore new opportunities to scale production and accelerate growth with support and consultancy from HP.

Learn

HP 3D as a Service

Pay based on usage: Gain new levels of cost predictability and the flexibility to scale your business as you grow.

Learn

HP Integrated Financial Solutions

Accelerate your time to value. Enjoy the flexibility to meet both your technology and financial plans while allocating your cash to other priorities.

LearnHP Case Studies

From prototyping to production, HP 3D HR PP enabled by BASF results in robust parts and shorter supply chains

Extol leverages the manufacturing industry’s familiarity with polypropylene combined with the capabilities of HP Multi Jet Fusion technology to help customers decrease time to market through design validation efficiency

Read more

Book a Consultation

We're here to answer your questions

Implementing a new technology can be a painful experience, slowing down your core business and not returning results immediately.

Let our team take your headaches away, our knowledge of integrating 3D printing into different industries and applications is second to none.

We’d love to hear about your project and help you find the right solution.