Meltio 3D Printers

THE NEXT LEVEL

Meltio revolutionises metal part manufacturing with state-of-the-art additive manufacturing solutions powered by its groundbreaking technology. Experience a paradigm shift as Meltio introduces an unprecedented solution that empowers companies, irrespective of their size, with an accessible, streamlined, and scalable manufacturing process.

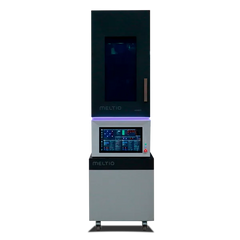

Meltio M450 3D Printer

Meltio’s Wire-Laser 3D Printer

Discover a cost-effective, reliable, user-friendly metal 3D printer for industries.

Available to order Now!

Meltio M600

The All-in-one Printing Platform

Improve manufacturing with blue lasers, large build area, inert chamber.

Available to order Now!

Meltio Robot Cell

Plug and Play Installation

A cost-effective, ready-to-use solution for Meltio Engine Robot Integration.

Available to order Now!

Meltio Engine Integration Kit for Vertical Machining Centres

Platform for Machining and Additive Manufacturing

Introducing Meltio Engine: an affordable hybrid solution for diverse CNC machines.

Available to order Now!

Meltio Engine Integration Kit for Industrial Robots

Large-Scale Metal 3D Printing

Transform any robot arm into a metal 3D printing system without inherent size constraints.

Available to order Now!

Single and Dual Metal 3D Printing

Meltio recommends printing the majority of the parts with metallic welding wire – the cleanest, safest and most affordable metal feedstock on the market

Single Wire

The bulk of the 3D printing process is built around wire, the safest, cleanest and easiest to work with metal feedstock.

Dual Wire

Combine different metal materials in a single part. The wire switching process is automatic, quick and clean.

First-Time-Right with Meltio Materials

Guaranteed part properties with optimized print profiles

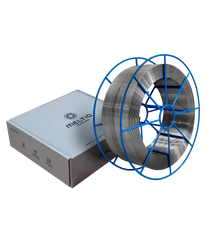

Meltio Stainless Steel 308L Wire spool 15kg, Ø1mm

All-round Stainless steel with adequate corrosion resistance and good mechanical properties.

All-round Stainless steel with adequate corrosion resistance and good mechanical properties. Technical Information Diameter: 1 mm Weight: 15 kg Volume: 1875 cm³ Density: 8.0 g/cm³ Spool type: BS300

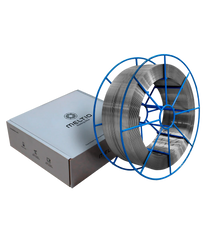

Meltio Titanium 64 Wire spool 7.5kg, Ø1mm

High strength Alpha+Beta alloy with excellent fracture toughness, corrosion resistance and biocompatibility.

High strength Alpha+Beta alloy with excellent fracture toughness, corrosion resistance and biocompatibility. Widely used in aerospace, marine, chemical and biomedical industries Diameter: 1 mm Weight: 7,5 kg Volume: 1704 cm³...

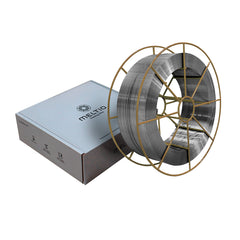

Meltio Nickel 718 Wire spool 15kg, Ø1mm

High strength nickel-super alloy with large working temperature range. Highly resistant against cracking while protecting well against corrosion.

High strength nickel-super alloy with large working temperature range. Highly resistant against cracking while protecting well against corrosion. Technical Information Diameter: 1 mm Weight: 15 kg Volume: 1829 cm³ Density:...

Meltio Mild Steel ER70S Wire spool 15kg, Ø1mm

All-round Stainless steel with adequate corrosion resistance and good mechanical properties.

All-round Stainless steel with adequate corrosion resistance and good mechanical properties. Technical Information Diameter: 1 mm Weight: 15 kg Volume: 1875 cm³ Density: 8.0 g/cm³ Spool type: BS300 Data Sheets...

Meltio Nickel 625 Wire spool 15kg, Ø1mm

A Ni-based superalloy with excellent mechanical properties at a wide range of temperatures.

A Ni-based superalloy with excellent mechanical properties at a wide range of temperatures. Among superalloys, Ni625 excels for its weldability, making it an ideal choice for cladding or repair of...

Meltio Tool Steel H11 Wire spool 15kg, Ø1mm

A chromium-based steel alloy, it’s one of the most commonly used tool steels, thanks to its outstanding impact toughness.

A chromium-based steel alloy, it’s one of the most commonly used tool steels, thanks to its outstanding impact toughness. H11 is widely used for hot tooling applications, in the manufacturing...

Meltio Stainless Steel 17-4PH Wire spool 15kg, Ø1mm

A martensitic precipitation hardened stainless steel capable of achieving high hardness while offering excellent corrosion resistance.

A martensitic precipitation hardened stainless steel capable of achieving high hardness while offering excellent corrosion resistance. It is widely employed in the oil & gas, aerospace, energy, and defense industries....

Meltio Stainless Steel 316L Wire spool 15kg, Ø1mm

Highly corrosion-resistant grade of austenitic stainless steel with great mechanical properties. Ideal for marine and chemical applications.

Highly corrosion-resistant grade of austenitic stainless steel with great mechanical properties. Ideal for marine and chemical applications. Stainless Steel 316L is an austenitic steel with excellent durability, good biocompatibility and...

Meltio Invar Wire spool 15kg, Ø1mm

This alloy gets its name thanks to its extremely low coefficient of thermal expansion, from -250°C up to about 200°C.

This alloy gets its name thanks to its extremely low coefficient of thermal expansion, from -250°C up to about 200°C. This feature makes it an ideal choice for measuring equipment,...

Unlimited Third-party Material Choice

Choose the ideal welding wire for your applications

Stainless Steels

Excellent strength and corrosion resistance.

Mild Steels

Cheap and ductile, with unparalleled machinability and weldability.

Carbon Steels

High impact strength, retain hardness at high temperatures.

Titanium

Highest strength to weight ratio and corrosion resistance.

Inconel

High versatility, outstanding heat and corrosion resistance.

Copper

Under Development.

Meltio Whitepapers

Meltio Materials Handbook

Meltio’s utilization of wire feedstock has resulted in enhanced control over material deposition...

Download

Meltio Design Guidlines

How to design with Meltio? Solve all your questions: geometry limitations, minimum vertical hole diameter, thin walls, overhang solutions, etc…

Download

Mold-Making with LMD and Dual Wire

In recent years, additive manufacturing (AM), also known as 3D printing, has emerged as...

DownloadCase Studies

Past. Present. Future

Mold with Conformal Cooling Channels

Plastic injection is one of the most affordable and widespread processes for mass production purposes in the industry of thermoplastic polymers. It involves four main stages: (i) injection of molten plastic, (ii) compacting in the mold, (iii) cooling process and (iv) mold ejection. The literature reviews indicate that the cooling stage constitutes approximately 70% to 80% of the total cycle time.

Book a Consultation

We're here to answer your questions

Implementing a new technology can be a painful experience, slowing down your core business and not returning results immediately.

Let our team take your headaches away, our knowledge of integrating 3D printing into different industries and applications is second to none.

We’d love to hear about your project and help you find the right solution.