Which support material is right for my print?

It is important for manufacturers to have a support strategy when using additive manufacturing technology, such as FFF extrusion. Print inaccuracies or print failures are common when 3D printing with any unsupported features such as arms or overhangs. Without the use of a support material it causes the filament to drip onto the plate until the print has cooled (known as dropping loops).

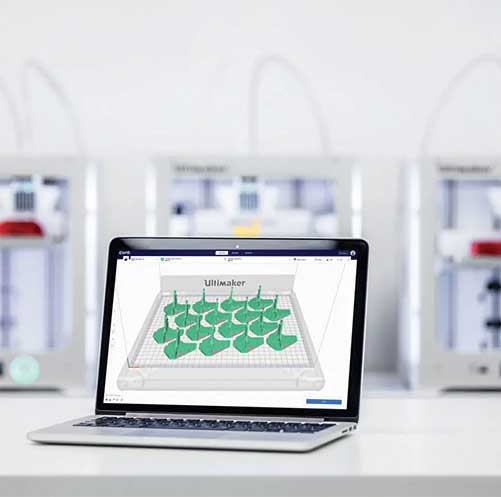

The solution is to use the primary build material for the print structures. Using open-source software such as Ultimaker Cura, support material generation should be activated indicating the angle at about 45-50 degrees. Ultimaker Cura has a number of options for support materials to be generated. Everything from using per object settings, placing custom designed support objects to experimental techniques such as tree support patterns.

By using dual extruder machines, starting with the Ultimaker 3 and following into the Ultimaker S-Line, the operator has the opportunity to build their parts with two materials at the same time. This opens up opportunities to print using dedicated support materials that are ideally suited to print support scaffolding. These materials are engineered to be easily removed from the primary build part without chipping, sanding and healing that was more typical when support scaffolds were printed using the primary build material.

Additional strategies are possible in Ultimaker Cura for single build support techniques that gain further value in a dual extrusion machine. It is now not only possible to choose a solution that perfectly matches the supports. You can also match the material selected for the primary build with exactly the right support material designed to reach the intended part faster. Architects designing model housing with supports on the outer perimeter of the object can use breakaway materials that do not chemically bond with the primary build material and can easily be pulled away from the surface using pliers. Alternatively, a part printed such as an anatomical heart has many intricate cavities. With these elements it would be impossible to remove by hand using simple single material strategies. In this case PVA and other water-soluble materials which are easy to use and easy to remove can save the day.

The benefits of using dedicated support materials include, design freedom with complex geometries, overhang angles that can be less that 45 degrees, ability to produce internal cavities and single-part hinges where removing the primary build support would have been impossible.

What to remember when using support materials

PVA is easy to use and remove with many of Ultimaker's lower temperature materials. However, it is not compatible with high temperature engineering materials or materials that simply won't bond. Breakaway material is ideal for fast removal when support features are on the outside but can be extremely difficult when extracting from internal cavities and highly complex organic surfaces. Using Ultimaker Cura with the ‘easy print’ and ‘intent’ based profiles makes activating support very easy. If in ‘custom mode’ Ultimaker Cura has even more to offer. There are a number of patterns that are not only great for finding the right way to support tricky parts geometries but also solutions such as giro infill that offers more surface exposure during dissolving.

Ultimaker PVA and Breakaway

PVA is compatible with PLA, tough PLA, CPE and Nylon. It is important to note that when using PVA support material to keep it out of moist environments. With PVA it is possible to print very intricate and small features and then easily dissolve the support material to be left with an exceptionally clean finish. Breakaway, as it says in the name supports can easily be pulled off, it is a very time efficient material. It is a better choice of support material when printing with high temperature engineering materials such as ABS, CPE+.

These two highly popular support materials are not without their limits. There are certain material bonding limitations when working with higher temperature materials. For example, Polycarbonate (PC), TPU 95A, Propylene (PP) each suffer from incompatibility. The approach taken for these materials is to produce the intended part using support structures printed in the primary build material.

Support with more challenging Ultimaker materials

Infinite Material Solutions LLC is dedicated to the development of novel, state of the art, user and environmentally friendly soluble support materials for additive manufacturing – using decades of experience and knowledge. Their team set out to target a dedicated support material filament that requires only tap water, agitation and heat to dissolve without requiring any chemicals or dissolving agents.

AquaSys 120 has been introduced to the Ultimaker portfolio and matches many more materials than the other available support products and within a wider range of processing temperatures.

Some of the key properties of AquaSys include versatility in material compatibility, works with a wide range of engineering thermoplastics (hydrophobic and hydrophilic) including ABS, PC, Nylon, TPU, CPE, and PP, fully water-soluble, excellent surface quality and better bonding means successful support for complex internal features.

Designing support materials is very complicated and many factors need to be considered. Such as excellent model adhesion, modulus and stiffness at high temperatures, high dimensional stability to avoid curling and warping, excellent self-adhesion for bonding and z-axis strength and water soluble in reasonable conditions. Infinite AquaSys 120 is ideal for many different applications with dissolving to leave a smooth finish it is ideal for prototyping varied, complex designs. Ability to dissolve faster meaning tooling can be in the hands of the operator more rapidly. Reduces per-part costs by cutting out costly post-processing with AquaSys.

Tips and Trick for Dedicated Support Material Usage

- Try to avoid using too much support material, using design for AM best practices. To avoid this print only an interface layer with support material.

- A similar way would be to decrease the amount of support with horizontal expansion settings. By doing this you can reduce the printing time.

- Import a custom mesh to create optimised support shapes.

- When using breakaway if there is too much adhesion, after removal there may be some white stripes on the surface. In this case the gap distance should be adjusted between the support and model. Other options include decreasing the surface temperature or print support and build material layer lines in the same direction.