Could this 3D printed material have the same impact as other medical breakthroughs?

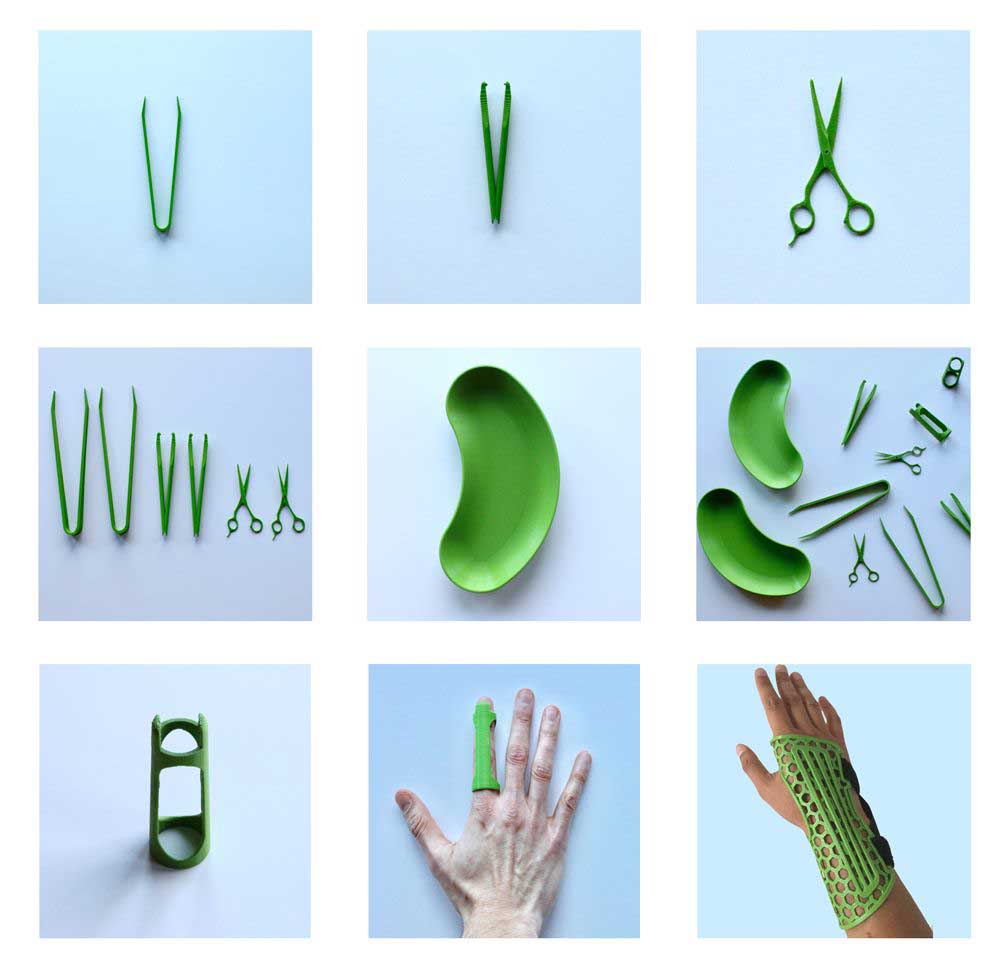

Copper 3D is a Chilean manufacturer of filaments and is widely acclaimed due to its antibacterial 3D printing materials, and is renowned for their properties and the addition of copper nanoparticles. Copper 3D was the first company in the 3D printing industry that proposed the concept of antimicrobial 3d printing. The interesting part of this concept is the impact of what you can do with the materials. There are a number of well known applications Copper 3D have manufactured such as, the Nano Hack mask, antibacterial mobile phone cases, door handle covers and the most recent concept which is an active bottle that purifies dirty water. Antibacterial action has been scientifically validated eliminating more than 99.99% of fungi, viruses, bacteria and a wide range of microorganisms. Copper 3D recently announced that their antimicrobial nano-composities have been tested and validated and has proven their materials are effective against the human Coronavirus strain 229E (HCoV-229E) under the EN14476 + A2 standard, achieving extraordinary results.

Copper 3D are hacking materials, making them clean/safe and disrupting the industry! With their innovative concepts they are reshaping the future and saving lives. Their portfolio of materials is scientifically tested in microbiology laboratories and has successfully approved the most demanding mechanical tests. For example PLACTIVE AN1™ is an innovative Nanocomposite developed with a high quality PLA and a patented, scientifically validated and highly effective Nano-Copper additive. PLACTIVE material is a mixture of 1% antibacterial nanoparticles and copper nanoparticles. The PLACTIVE is FDA registered and has an ISO 9001/2015 certification. Other materials by Copper 3D include Nanoclean and Flex. MD1 Flex is an innovative Nanocomposite developed with a high quality TPU98A and a patented, scientifically validated and highly effective Nano-Copper additive.

Looking into the future it is estimated that by the year 2050, considerably more people will be living with amputations. Finger amputations are one of the most common amputations of upper limbs. Although there have been many advances in upper limb prosthetics, there is a high rate of user abandonment. It is common that upper limb amputees reject or abandon their prosthesis. The use of transitional prostheses decreases the burden on the contralateral limb, increases function by offering an additional grasp with bimanual tasks, assists in body symmetry, and improves self-image. It has been reported that the use of an immediate post-operative functional prosthesis (i.e., a transitional prosthesis) can also improve the range of motion and strength of the affected hand. However, these functional transitional devices are often made by hand, requiring long construction times and highly skilled technicians to manufacture them. It has been shown that copper compounds have a high potential for use in the development of low-cost medical devices with powerful antibacterial properties. These positive characteristics and the high environmental safety of copper makes it capable of replacing silver and other antimicrobial compounds in the development of a wide range of medical devices. With the advancements in additive manufacturing (i.e. 3D printing) and new antimicrobial 3D printing filaments such as Copper 3D it offers the unique possibility of manufacturing low-cost, customisable, and antibacterial 3D printed prosthetics.